Category

- Fiberglass Grating

- Molded Grating

- Pultruded Grating

- Fiberglass Structural Shapes

- Fibreglass Flat Panels

- Fiberglass Tube

- Fiberglass Rod

- Fiberglass Beam

- Fiberglass Channel

- Fiberglass Angle

- Fiberglass Bar

- Fiberglass Deck

- Fiberglass Stair Treads

- Fiberglass Handrail System

- FRP Handrail

- FRP Handrail Fittings

Fiberglass Pultruded Handrail System

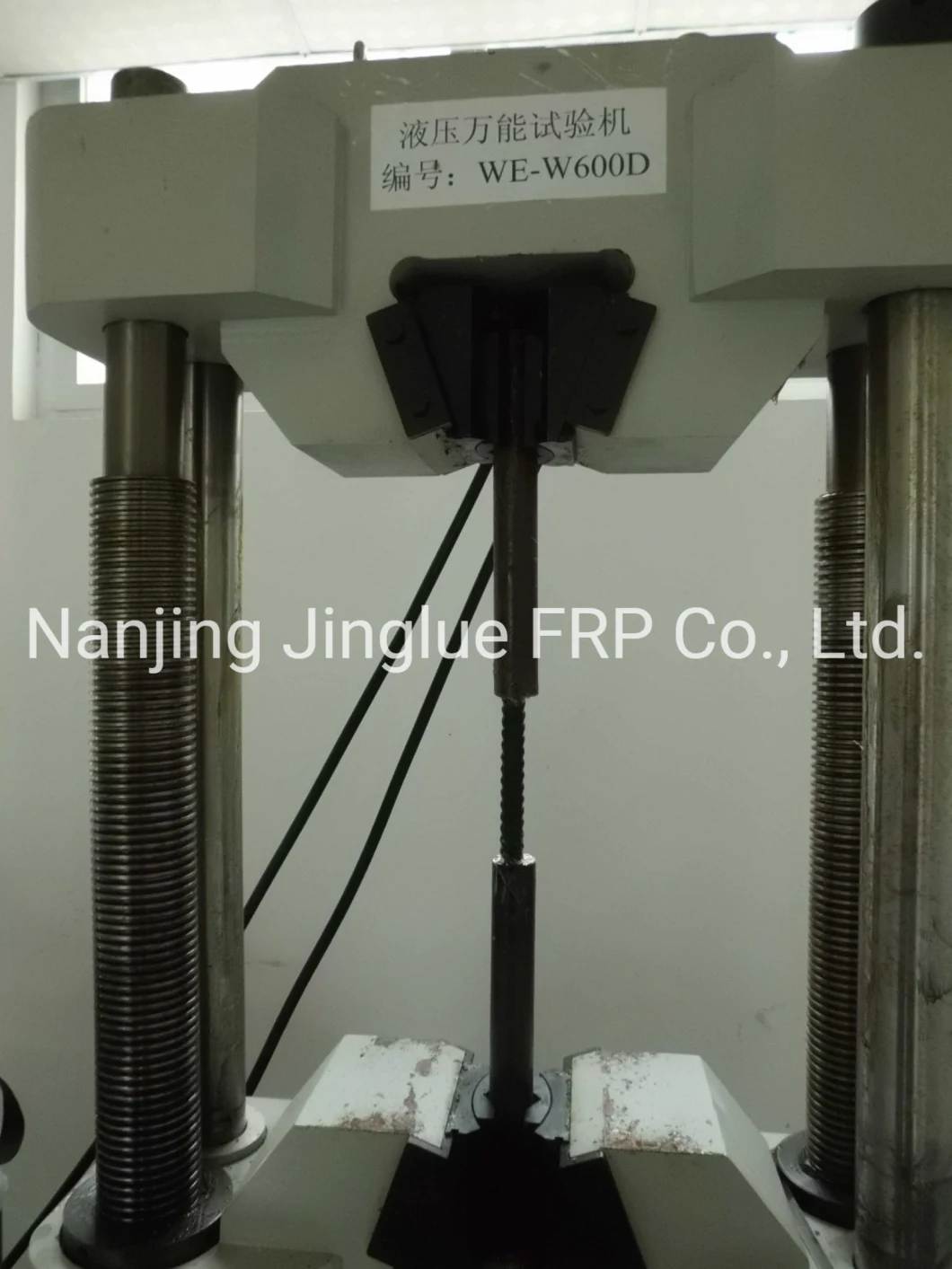

1. Properties of FRP pultruded profilesA. High strengthFRP is stronger than structural steel on a pound-for pound basis.

Basic Info

| Model NO. | FRP Handrail Parts |

| Transport Package | Pallet, Plastic Bag, Carton, etc. |

| Trademark | JLF |

| Origin | Nanjing, China |

| HS Code | 3626909090 |

Product Description

1. Properties of FRP pultruded profilesA. High strengthFRP is stronger than structural steel on a pound-for pound basis. It has been used to buildings, walkway, sub-floors and platforms.B. Light weightFRP is 20-25% the weight of steel and 70% the weight of aluminum. FRP are easily transported, handled and lifted into place. Total structures can often be preassembled and shipped to the job site ready to installation.C. Anti-corrosionFRP will not rot and are impervious to a broad range of corrosive elements. This feature makes FRP a natural selection for indoor or outdoor structures in pulp and paper mills, chemical plants, water and sewage treatment plants, structural near salt water and other corrosive environments.D. Electro-magnetic transparencyFRP are transparent to radio waves, microwaves and other electromagnetic. It is widely used to make antennas.E. Non-conductiveFRP has low thermal/ electrical conductivity.F. Dimensional stabilityThe coefficient of thermal expansion of FRP is slightly less than steel and significantly less than aluminum.G. AestheticsFRP are pigmented throughout the thickness of the part and can be made to virtually any desired custom color. Special surfacing veils are also available to create special surface appearances such as wood grain, marble, granite, etc.2. Craft Fiberglass pultruded profiles are manufactured with the pultrusion process after choosing the correct raw materials major including the resin, fibers and additives according to the profiles requirement including mechanical strength, electrical insulation, anti-corrosion etc.Fiberglass pultruded profiles can meet the customer's requirements by using different combination of resin, fibers and others.Fiberglass pultruded profiles offer a unique combination of chemical resistance, size stability, high strength, and thermal/electric non-conductivity, etc.3.ApplicationsThe above FRP profiles are often used as handrail parts, structural members, platforms, walkways,etc.4. Some available specifications of FRP handrail system.Above is the brief introduction of our hanrail system. The height is 1100mm. The distance between the columns is 1000mm. The columns, rails and Kick boards are connected together by a series of suitable fittings and frp molded bases which are at last fastened to the ground

Besides these standard barriers, customer-designed specifications are also welcomed.

5. Following is General Physical Parameters of FRP Pultruded Profiles.(If have special requirements, pls contact Nanjing Jinglue.)

LW-lengthwise CW-crosswise PE=perpendicular to laminate face

| Mechanical performance | Value | Units | Test method | ||||||

| Tensile strength | LW | 230-600 | Mpa | ASTM D-638 | |||||

| CW | 45-80 | ||||||||

| Tensile modulus | LW | 18-30 | Gpa | ASTM D-638 | |||||

| CW | 7-13 | ||||||||

| Flexural strength | LW | 300-700 | Mpa | ASTM D-790 | |||||

| CW | 80-120 | ||||||||

| Flexural modulus | LW | 20-26 | Gpa | ASTM D-790 | |||||

| CW | 7-12 | ||||||||

| Compressive strength | LW | 280 | Mpa | ASTM D-695 | |||||

| CW | 105 | ||||||||

| Compressive modulus | LW | 21 | Gpa | ASTM D-695 | |||||

| CW | 7.9 | ||||||||

| Interlayer shear strength | LW | 25 | Mpa | ASTM D-2344 | |||||

| Impact strength | 280 | KJ/M2 | ASTM D-256 | ||||||

| Physical property | Value | Units | Test method | ||||||

| Barcol Hardness | 50 | --- | ASTM D-495 | ||||||

| Water absorption(25 Centigrade,24h) | 0.2-0.5 | % | ASTM D-570 | ||||||

| Density | 1.75-2.00 | g/cm3 | ASTM D-792 | ||||||

| Coefficient of thermal expansion(LW) | 5.0 | 10-6/Centigrade | ASTM D-696 | ||||||

| Coefficient of thermal conductivity | 0.4 | W/(m.K) | ASTM C-518 | ||||||

| Elongation to break | 0.9 | % | ASTM D-638 | ||||||

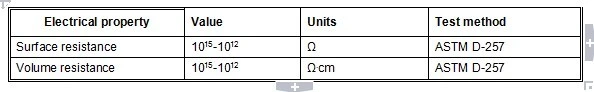

| Electrical property | Value | Units | Test method | ||||||

| Arc resistance(LW) | 120 | seconds | ASTM D-495 | ||||||

| Dielectric constant(PF) | 5 | @60hz | ASTM D-150 | ||||||

| Dielectric strength(PF) | 8 | KV/mm | ASTM D-149 | ||||||

| Dielectric strength(LW) | 1.6 | KV/mm | ASTM D-149 | ||||||

| Flammability property | Value | Units | Test method | ||||||

| Tunnel test | Max 25 | second | ASTM E-4 | ||||||

| Oxygen data | 25-28 | % | ASTM 2863 | ||||||

| 28-32 | |||||||||

| >32 | |||||||||

| Flammability classification | Self extinguish | ASTM D635 | |||||||